Subtotal: $

Checkout

When we moved to our ten-acre farm in southern Minnesota seven years ago, with a toddler and a newborn in tow, our main idea was to experience country life. To plant a garden, perhaps raise a few chickens. We didn’t expect much else to change.

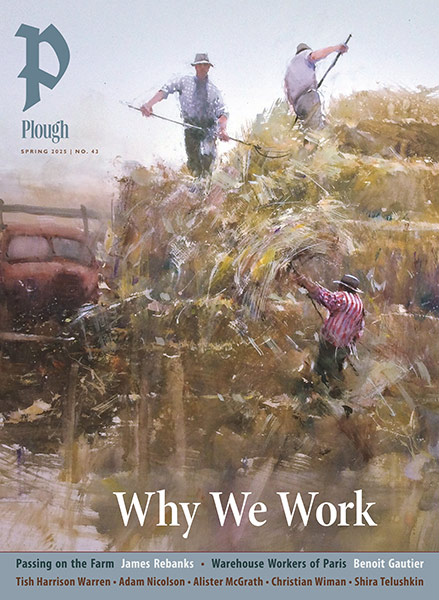

The gardens are here, to be sure. So are sheep, goats, pigs, and honeybees. On any given day, we also find ourselves baling hay, pitching manure, splitting wood, and repairing fences. Always repairing fences. At some point our hobby farm became a working farm, and nearly every aspect of our lives is now centered on this labor we undertake together, as a family.

The chickens are here, too. When we first started raising them to sell, we had no idea how to turn the grown birds into oven-ready broilers. We found a butcher shop nearby that would process and have them ready for pickup the following day, bagged and frozen, for two dollars a bird. Try to imagine everything entailed in butchering a chicken: killing, plucking, gutting. Two dollars was a deal we couldn’t pass up.

But … I was interested. One day, on a whim, I asked the butcher if she ever needed part-time help. “Are you good with a knife?” she asked me. “No,” I replied, “I’m a computer programmer!” A few weeks later I got a call: “Do you still want to work here?”

My first day at Dennison Meat Locker was grueling. I was thrown into the fray from the beginning. There was no employee orientation, safety video, not even a tour. Instead I was shown once how to clean a hanging side of beef, cutting away excess fat and tissue, and then handed a knife as my teacher walked away to skin another cow.

On a typical day we slaughtered six beef cattle, four to six hogs, and several sheep or goats. On poultry days we processed up to 1,200 chickens. Once we finished slaughtering, cleaning, weighing, and refrigerating, we still had two hours of cleanup. You haven’t cleaned anything until you’ve cleaned a kill room.

For me, learning the ancient trades of farming and butchering felt unreal. I was used to writing code in a comfy chair in an air-conditioned office. After my first day as a butcher, I wondered why these were the low-paying jobs.

The work of historic trades is real. It’s dirty, smelly, sweaty, tremendously physical, and often dangerous. Skinning and gutting. Cutting, splitting, and stacking firewood. Weeding, mulching, and harvesting from the garden. Hauling water and cleaning stalls. There are easier ways to acquire food. Cleaner ways. Cheaper ways. As a friend recently quipped, growing tomatoes is “the best way to devote three months of your life to saving $2.17.”

But that’s not why we do it.

Photo by L ley (public domain)

Food has never been cheaper or more abundant than it is today. According to the Bureau of Labor Statistics, US expenditures on food have dropped from 42.5 percent of the annual household budget in 1901 to a mere 10.5 percent in 2017. This easy availability of food, unimaginable in previous centuries, is the result of our industrial agricultural system with its factory farms.

Modern agroindustry represents one of the later stages of the Industrial Revolution, which by the end of the nineteenth century had upended the traditional, crafts-based economy. Prices plummeted thanks to increased productivity, and families could seek profitable employment in factories. A Massachusetts Bureau of Labor Statistics report from 1885, for example, includes enthusiastic praise for the factory system, noting that, prior to the Industrial Revolution:

Nothing was known of the development of special skill by the subdivision of labor and the confinement of each workman to one particular step in a series of progressive operations, an expedient by which the productive capacity of the modern operative has been brought to the maximum and the time required to complete the product reduced to the minimum.footnote

Yet in important ways, cheap goods came at a high price. The depressed prices for commodities forced many subsistence farmers into factory work; the efficiency of factory production meant that anyone attempting to preserve artisanal skill by making products in smaller workshops was handily outcompeted. Both farms and workshops ceased to operate as they had for centuries.

What vanished with them was a way of raising the young that had been standard since time immemorial. In the preindustrial way of life, young people often worked on family farms, working alongside their parents, or they gained knowledge of their life’s work as apprentices, toiling intimately alongside a master who taught them every step of their craft, with whose family they lived, and who was also charged with their moral instruction. Of course, the system did not always work as it was intended to; neglect and abuse were always a possibility. Still, there was some attempt to live out this ideal of close discipleship, close training in the practical skills and virtues. With industrialization, opportunities for that kind of formative relationship became rare. Parents who must leave each morning to go to jobs elsewhere can no longer spend large portions of their day educating and mentoring their children at home. Reliance on family and community is replaced with reliance on the employer. Work is no longer a context for older generations to transmit faith and values to the next generation.

Livelihoods that once lasted centuries, passed down from generation to generation – blacksmith, cooper, basketmaker – have all but disappeared. Meanwhile, the industry at the cutting edge of modern employment tends to encourage frequent job change. Tech has an annual turnover level of 13.2 percent, the highest turnover level of any industry, including the famously volatile service industry.

Constant job changes aren’t necessarily by choice. For example, in my field of software engineering, someone who does not constantly acquire new skills will become obsolete in about three years. I vividly remember my first day as a self-employed computer consultant. A client who had hired me to help with a custom software project gave me a tour of the sprawling startup’s headquarters. The supervisor showed me the free soda machines, the communal working environments, the breakrooms replete with ping-pong tables and other games. I was told about a forthcoming JumboTron for Friday afternoon movie screenings.

The next day everyone was laid off – including me. It was the beginning of the dot-com collapse.

This was a more dramatic version of a story that has been playing out in American industry for upward of a century. If it takes years, even decades, to effectively disciple another person, what does that mean for the American worker who switches jobs every few years? We have become experts at training employees for productive capacity, but who is looking out for their moral acuity? Who is watching for mental and emotional balance, the health of the whole person – even to the risk of the bottom line?

In terms of material abundance, we are vastly richer than our forebears. But if quality of life consists merely of the abundance of possessions; if one’s value to society is based solely on one’s productive capacity; if things, careers, and people are perpetually becoming obsolete – what have we profited by gaining the whole world?

Scripture makes it clear that work is not solely about making stuff. God intended something else to occur in the process. We may be growing tomatoes or crafting fine furniture. But we are also shaping souls.

It is at work that true discipleship takes place, more than at church or in the classroom. Work is where the real person resides. The nature of a man is revealed when he is swinging a hammer, felling a tree, or negotiating a contract. For good or ill, we speak loudest to those around us when we are at work. Integrity, perseverance, and faith in divine providence: these things cannot be transmitted in a lecture hall. They must be modeled.

The apostle Paul mentored Aquila and Priscilla while working: “because he was a tentmaker as they were, he stayed and worked with them.” (Acts 18:3). He also admonished the Thessalonian church to “acknowledge those who work hard among you. … Hold them in the highest regard in love because of their work” (1 Thess. 5:12–13).

That is why we don’t mind the sweat and dirt, or the inefficient methods of production we employ here on our farm. My old skills as a computer programmer are already obsolete. But my newfound skills with a knife are not; I can pass them on to my children.

For us, it’s not about doing it faster or cheaper. Relationships are what matter. I want to be there beside my son as he struggles to lift bales into the barn, or kneel beside my toddlers as they pick blueberries (even if as much fruit goes into their mouths as into the bucket). Working with my children in the garden, I can tell them about our responsibility to care for God’s creation. They get to see how their dad reacts to uncooperative weather, broken-down tractors, and raccoons in the henhouse. In these trying moments, will I give in to anger and anxiety, or will I demonstrate my faith by trusting in God’s provision?

It is at work where our faith is most on display. It is here that disciples are made.Footnotes

Massachusetts Bureau of Statistics of Labor and Carroll Davidson Wright, Comparative Wages, Prices and Cost of Living. Mass Bureau of Statistics of Labor, for 1885 (Reprinted Boston: Wright & Potter Printing Co., 1889) 10.

Rory Groves lives with his wife and five children on a farm in southern Minnesota, where they host educational workshops on traditional skills. He is the author of Durable Trades: Family-Centered Economies That Have Stood the Test of Time.

Already a subscriber? Sign in

Try 3 months of unlimited access. Start your FREE TRIAL today. Cancel anytime.